I. FRP Santiago Purlin.

1. Location and purpose of using Santiago purlin?

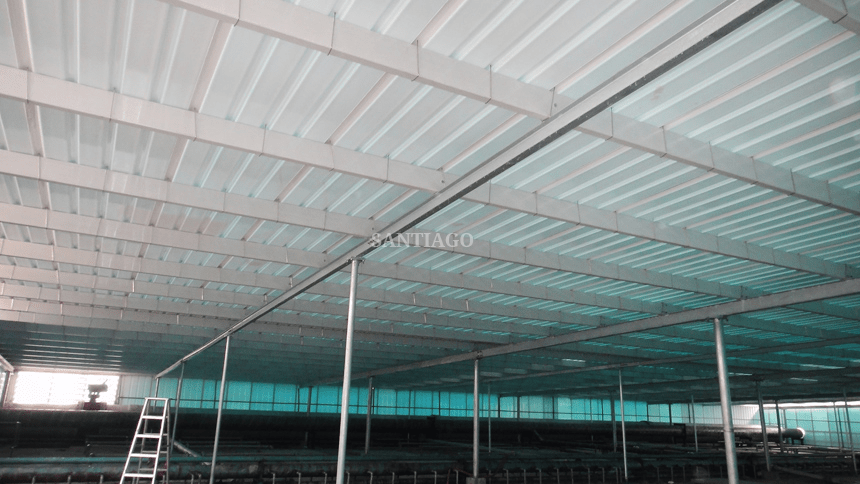

Purlin - The most frequently used in roofs and structures for the framework in buildings. The role of the plastic purlin will alter depending on where it is used:

- Roof purlins: These are used to support roofs on building projects; in order to hold the weight of the roof and prevent it from breaking down.

- Purlins: Used to support floors in building projects; in order to support the load from the floor as well as avoid the floor from bending.

- Cladding purlins: These are used to cover walls in building projects; in order to support the weight of the wall and avoid bending.

- Frame purlins: These are used to create frames for building projects; in order to join other parts and give the frame the necessary shape.

2. What is the role of FRP Santiago Purlin in real life?

- Used to create trusses for building projects.

- Used to create equipment for building projects like bridges, highways, transportation, etc.

- Used in farming to create trellises for growing plants.

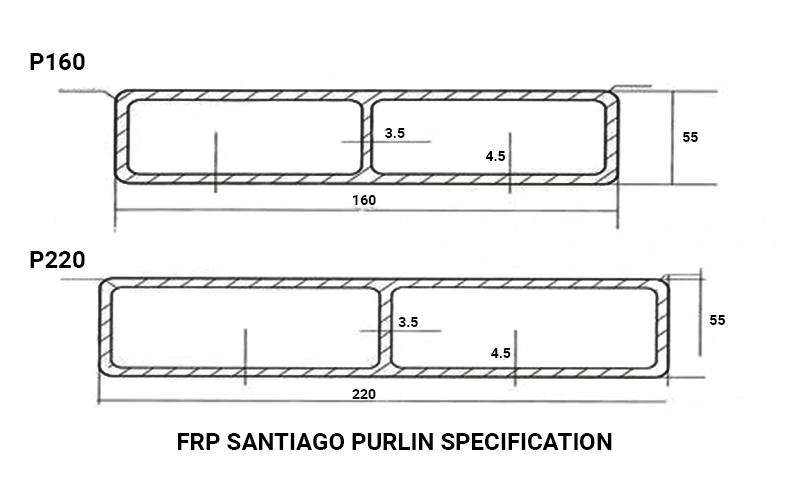

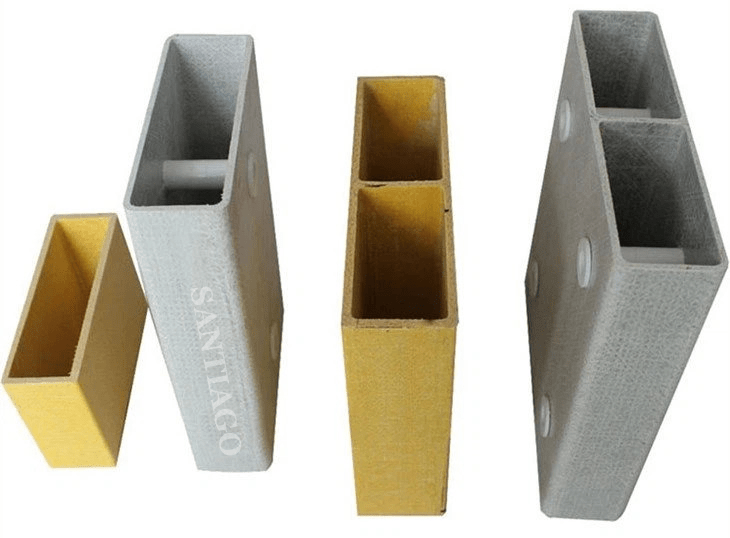

II. FRP Santiago Purlin Specification.

1. Santiago 160 Purlin.

- Length: 6000mm +/- 10mm

- Width: 60mm +/- 1mm

- Height: 160 +/- 1mm

- Thickness: 4.6 +/- 0.6mm

- Weight: 4.0 +/- 0.3kg/m

- Density: 1.9g/cm2

2. Santiago 220 Purlin.

- Length: 6000mm +/- 10mm

- Width: 60mm +/- 1mm

- Height: 220 +/- 1mm

- Thickness: 4.5 +/- 0.5mm

- Weight: 5.5 +/- 0.3kg/m

- Density: 1.9g/cm2

III. Why should you choose the FRP Purlin from Santiago.

1. Light weight, easier to move.

In comparison to steel purlins, Santiago purlins weigh just 1/15 as much. In comparison to wooden purlins, 1/10.

The weight of the building's construction may be greatly decreased thanks to FRP Santiago purlins, which reduces stress on the base and load-bearing columns. Santiago purlins reduce shipping and installation costs by removing the need for big equipment like welding and cutting machines. Like steel purlins, Santiago purlins don't need regular coating or maintenance frames made of wood.

Easier to move - Santiago.

2. Anti-corrosion, anti-rust, less negative impact from weather.

Made of fiberglass-reinforced plastic (FRP). Acids, bases, solvents, salts, and other chemicals don't corrode FRP plastic very well. When faced with environmental factors, FRP plastic does not corrode, break down, or go away. This makes it such that FRP plastic purlins have excellent corrosion resistance and won't rust over time like steel purlins or become prone to termites or damage from weather like wood purlins.

Anti-corrosion, anti-rust, less negative impact from weather - Santiago.

3. Conducts electricity and heat poorly, bringing a sense of security.

Compared to steel purlins, FRP Plastic Purlins have worse thermal and electrical conductivity. This means that when exposed to a power source, FRP Purlins do not heat up, have electric current run through them, or get electrified.

According to a research, steel has an electrical conductivity of 106 S/m, compared to 106 S/m for FRP.

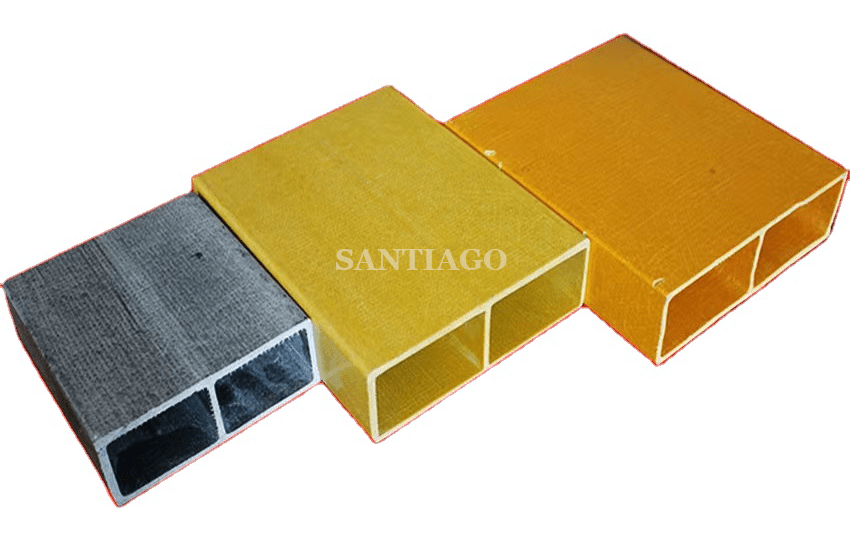

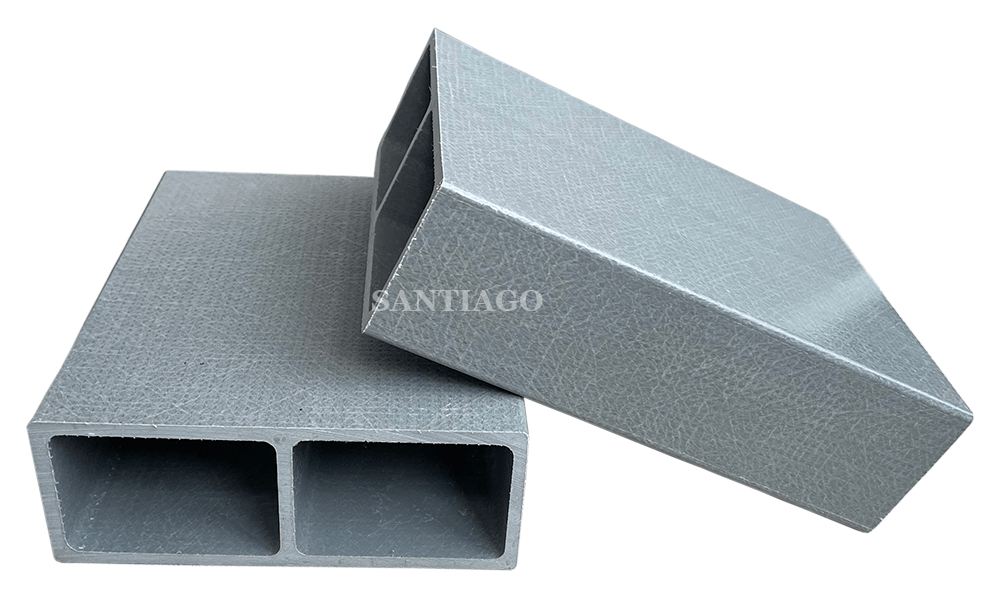

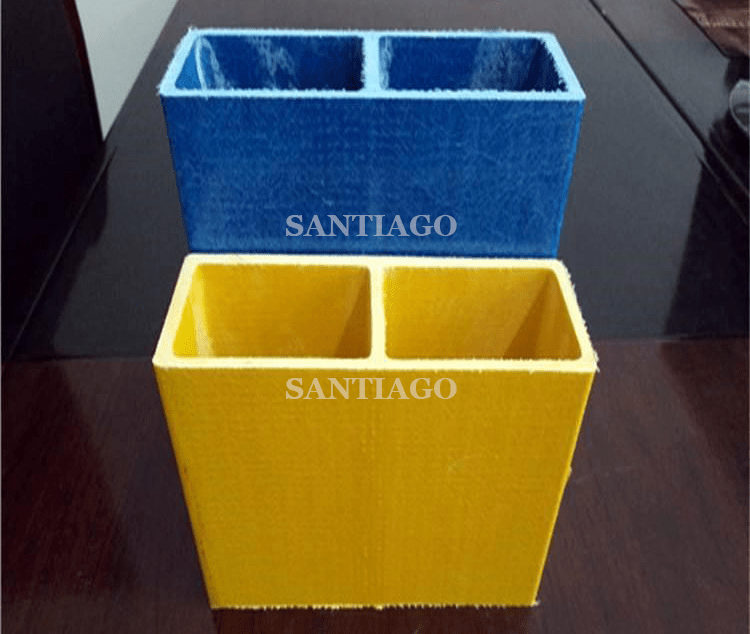

4. High aesthetics, suitable to different kinds of design.

FRP plastic purlins offer a range of options as opposed to typical purlins. FRP plastic purlins offer outstanding beauty and a wide range of color and size possibilities, providing clients many choices to match their own style.

Additionally, FRP purlins have a smooth surface, are less likely to pick up dirt, and are cleaner than before. They are also highly resistant to weather and natural influences, which contributes to their extremely high color fastness.

IV. FRP Santiago Purlin construction instructions.

V. FRP Santiago Purlin – The Complete FAQ Guide.

1. How many types of plastic purlins are there and what are the differences between them?

There are three varieties of plastic purlins:

- PVC purlin: Plastic produced from polyvinyl chloride (PVC) is used to make this kind of purlin.

- PVC purlins offer the benefits of being lightweight, simple to drill, punch, install, and maintain. Additionally, PVC purlins offer rare heat, fire, and corrosion resistance.

- Cons: not recyclable, not resistant to sunshine, and easily affected at high temperatures. PVC purlins are frequently employed for modest, sizeable, and sudden constructions.

FRP Purlin - Santiago.

- Composite plastic purlin: This kind of purlin is constructed out of composite plastic, a material made up of plastic and reinforced fibers like glass, carbon, and natural fiber...

- Composite material plastic purlins offer the advantages of being strong, heat resistant, long-lasting, and hard. Additionally, composite plastic purlins provide rare UV protection, fire resistance, and corrosion resistance.

- Weighty, challenging to cut, punch, and more costly than PVC purlins are some of its drawbacks.

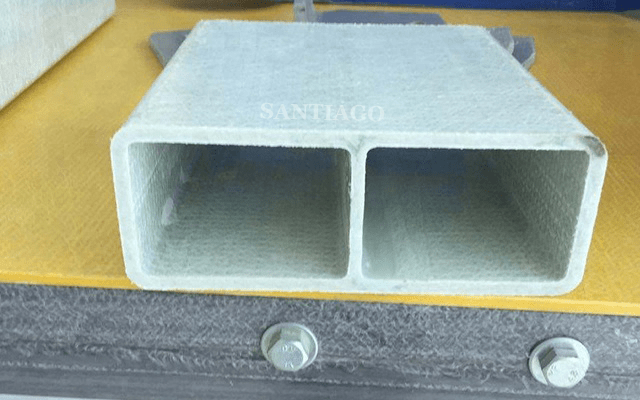

- Fiberglass Reinforced Plastic (FRP) Purlin: This kind of purlin is composed of FRP plastic, also known as composite plastic combined with glass fibers.

- FRP plastic purlins are advantageous in that they are light, rigid, long-lasting, high-strength, and heat-resistant. Additionally, FRP plastic purlins provide rare UV protection, fire resistance, and corrosion resistance. The colors and forms of FRP plastic purlins are also varied, making them suitable for a variety of designs.

- Disadvantages: PVC and composite plastic purlins are less costly than FRP plastic purlins. FRP plastic purlins can be used for construction projects that call for a high level of and resistance to severe weather.

FRP Purlin - Santiago.

2. Advantages and disadvantages of FRP plastic purlins?

Advantages of FRP plastic purlins:

- Light weight, easier to move.

- Anti-corrosion, anti-rust, less negative impact from weather.

- Conducts electricity and heat poorly, bringing a sense of security.

- High aesthetics, suitable to different kinds of design.

Disadvantages of FRP plastic purlins:

PVC and composite plastic purlins are less costly than FRP plastic purlins. FRP plastic purlins can be used for construction projects that call for a high level of and resistance to severe weather.

High aesthetics, suitable to different kinds of design - Santiago.

3. What is the bearing capacity of FRP plastic purlins?

You can refer to the table below:

VI. About us - SANTIAGO.

SANTIAGO IMPORT EXPORT COMPANY LIMITED

Head office : 2nd Floor, No.39 Do Nhuan Streat, Hoa Minh Ward, Lien Chieu District, Viet Nam

Hotline : (+84) 965437316 - Mrs.Lily

Gmail : salesantiagoroofing@gmail.com

Website : santiagoplastic.com