1. Plastic Formwork Santiago.

Formwork is molds into which concrete or similar materials are either precast or cast-in-place.

The plastic formwork from Santiago has been enhanced to make it easier to handle and uses. Santiago plastic formwork makes transit easier and upkeep seldom ever requires any effort.

Santiago plastic formowrk.

1.1 What is the role of Santiago plastic formwork in life?

- Construction: Help in the creation of concrete molds, partitions, lining floors, decorations, etc.

- Industry and the environment: Santiago plastic formwork is used in chemical storage tanks, wastewater treatment systems, and other applications due of its ability to resist chemicals.

- Advertising and communication: making billboards, banners,...

Creation of concrete molds - Santiago.

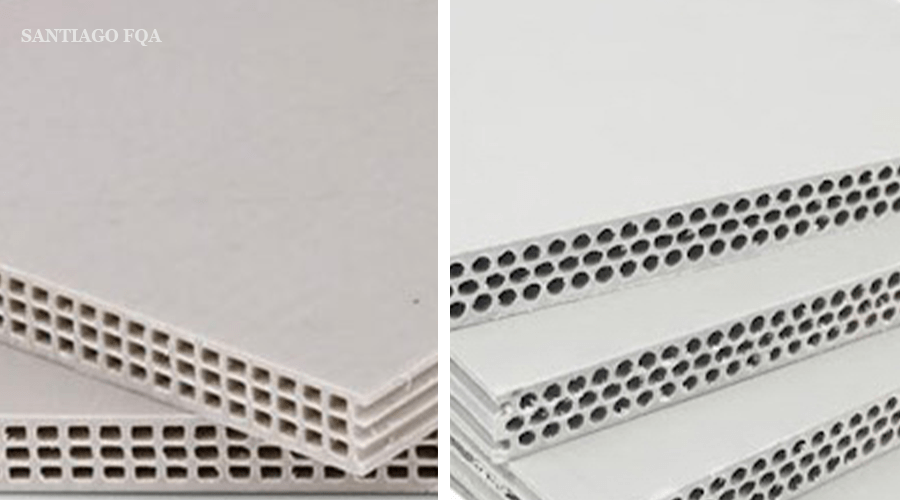

1.2 Structure of Santiago plastic formwork?

The Santiago plastic formwork has two parts:

- PP plastic (Polypropylene) is a flexible plastic with excellent heat resistance and great mechanical strength. In addition, it has excellent levels of chemical and corrosion resistance, which helps the product in many ways.

- Other additives: improve the product's capacity to stand up to weather and keep its looks.

2. Plastic Formwork Santiago Specification.

Santiago plastic formwork is available in two common weights and sizes.

Unit: mm

Length 2440 x Width 1220 x Thickness 15 (Model 1) ► 27kg - 28kg

Length 2440 x Width 1220 x Thickness 18 (Model 2) ► 29kg - 31kg

Note:

- Weight changes based on the size and form of the product.

- Size orders are possible upon request.

3. Why should you choose the plastic formwork from Santiago?

3.1 High durability and resistance to corrosion.

Santiago plastic formwork is a new type of formwork, made from high-quality PP (polypropylene) plastic, combined with other additives to enhance hardness and heat resistance. Santiago plastic formwork has high durability, high hardness, is waterproof, non-deformable, easy to construct and reuse.

Santiago plastic formwork.

Santiago plastic formwork is made of PP plastic and is lightweight, durable, strong, and easy to stack. Additionally, it may be employed in a variety of building settings and has the following qualities: fireproof, high heat insulation, water resistance, and acid and alkali anti-corrosion.

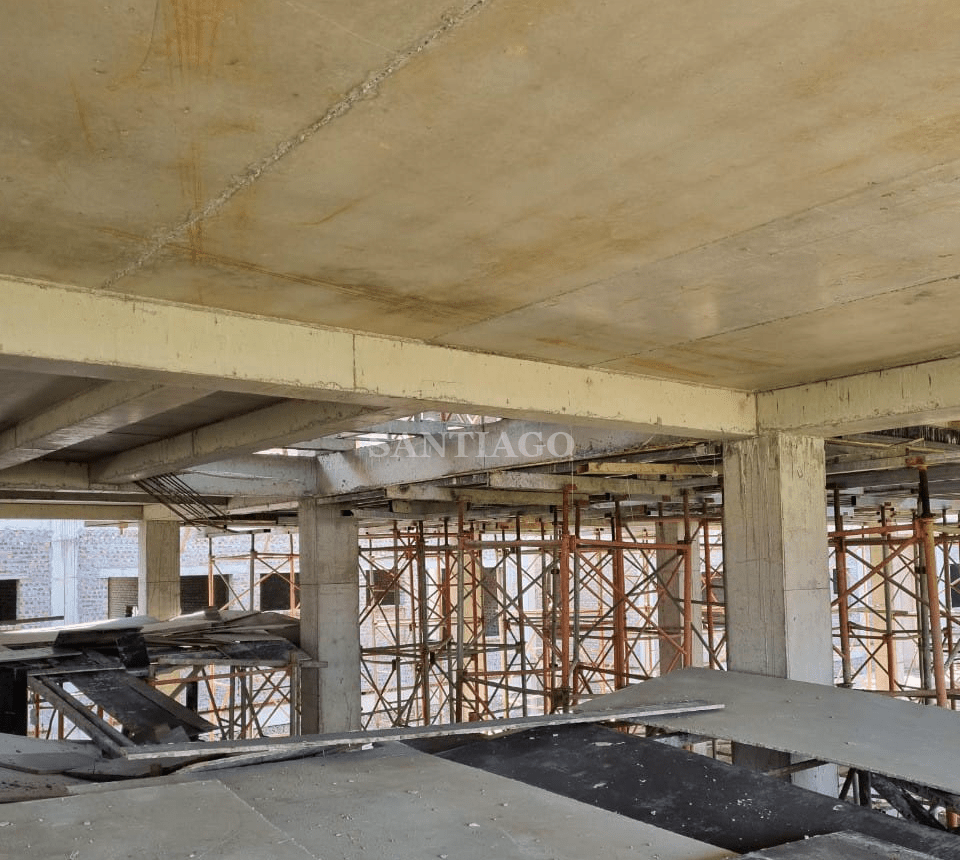

3.2 The ability to shape the surface.

The PP plastic formwork has a very smooth surface that makes it difficult for it to connect with the concrete and can provide the appearance of fair-faced concrete. The PP plastic formwork does not need to be sprayed with a release agent during construction since after the pouring is finished and the concrete has set up, the formwork immediately breaks down from the concrete and can be removed very easily.

3.3 Light weight, easy to move.

Santiago plastic formwork weighs only about 12% of steel formwork, 35% of aluminum formwork. This is a huge difference, showing that Santiago plastic formwork has a superior weight advantage compared to other types of formwork.

Construction easier - Santiago.

Easy to move - Santiago.

3.4 Long lifespan, can be reused many times.

Poured concrete doesn't stick to the plastic, and there are no dangerous chemical reactions. They are incredibly simple to clean with only water once the concrete has dried and the formwork has been taken down. Not only that, it can also be reused up to 30 times, helping to save costs.

Can be reused many times - Santiago.

4. Santiago plastic formwork construction instructions.

We would like to introduce the construction process of Santiago Plastic Formwork in the most specific and effective way. Besides, we also hope that through this video, you will have an objective view of Santiago's Plastic Formwork products.

Instructions for constructing Santiago plastic formwork.

5. Plastic Formwork – The Complete FAQ Guide.

(1). How many types of plastic formwork are there?

Depending on the size, thickness, shape, and quality of the plastic panels, there are several varieties of plastic formwork available. Several well-liked styles of plastic formwork include:

- Plastic formwork with square holes features a broad structure and equal-sized holes to enhance bearing capacity and lighten the formwork. The advantage of this kind is that it is simple to install, versatile, and has a shiny, spotless concrete surface.

- Plastic formwork with round holes has the same basic construction as formwork with square holes, except they are round rather than square. Better bearing capacity, no warping, no adherence to concrete, and acid and alkali resistance are all benefits of this kind.

(2). What Are the Pros of Using Plastic Formwork?

Compared to other kinds of formwork, plastic formwork has numerous benefits, including being lightweight and being simple to transport, put together, and remove.

- High durability; many uses possible.

- High-quality concrete surfaces are provided by the surface, which is smooth, bright, clean, and does not stick to the concrete.

- Waterproof, mold-free, and resilient to environmental effects.

- Anti-corrosion, resistant to acids and alkalis.

- Simple to cut, mix, and shape into many different sizes and shapes.

- The product is environmentally friendly and recyclable.

(3). What Are the Cons of Using Plastic Formwork?

The following are the drawbacks of employing plastic formwork for your building project, but, for the benefit of everyone:

- Although they are resilient and flexible, they are sensitive to heat.

- Plastic formwork, plastic molds, and initial investment expenses are all more costly than traditional forms of formwork.

- To ensure quality and safety throughout construction, careful oversight is necessary.

(4). How to install plastic formwork?

You can see how to install it at:

Instructions for constructing Santiago plastic formwork.

(5). How is plastic formwork different from traditional formwork?

Each type of formwork has its own advantages and disadvantages, depending on their characteristics, quality and cost. Here are some differences between plastic formwork and traditional formwork:

Plastic formwork is a type of formwork made from hard plastic, usually PP (polypropylene) or composite. Plastic formwork has a wide structure, with square or round holes to increase bearing capacity and reduce weight.

Plastic formwork has many advantages compared to traditional formwork, such as:

- Light weight, easy to transport, install and dismantle.

- High durability, can be reused many times.

- The surface is smooth, bright, clean, does not adhere to concrete, giving high quality concrete surfaces.

- Waterproof, not moldy, not deformed under the impact of the environment.

- Acid and alkali resistant, anti-corrosion.

- Easy to cut, shape and combine to different sizes and shapes.

- The product can be recycled and does not pollute the environment.

The traditional types of formwork include wood formwork, steel formwork, aluminum formwork and plywood formwork. These types of formwork have different advantages and disadvantages compared to plastic formwork:

- Wood formwork has the advantage of being light, easy to install, good bearing and easy to cut into many different modular shapes. The disadvantage of wooden formwork is that the surface quality decreases with the number of uses, the number of reuses is low, it consumes a lot of natural resources and causes environmental pollution.

- Steel formwork has the advantages of high accuracy, can be reused many times and construction of good quality concrete surface. Disadvantages of steel formwork are heavy weight, difficult transportation, time-consuming construction, easy to warp, warp, adhere to concrete, unsafe and high maintenance costs.

- Aluminum formwork has the advantage of being light in weight, not rusty, good for concrete surfaces and can be reused many times. The disadvantages of aluminum formwork are complicated construction and installation, high maintenance costs, and high production or purchase costs.

- Plywood formwork has the advantage of being light and easy to install, easy to cut into many different modular shapes, flat surface and low price. Disadvantages of pressed wood formwork are the low reuse rate, the surface quality decreases with the number of uses and the need for storage for storage.

6. About us - Santiago.

SANTIAGO IMPORT EXPORT COMPANY LIMITED

Head office : 2nd Floor, No.39 Do Nhuan Streat, Hoa Minh Ward, Lien Chieu District, Viet Nam

Hotline : (+84) 965437316 - Mrs.Lily

Gmail : salesantiagoroofing@gmail.com

Website : santiagoplastic.com